- +1-781-281-7976

- [email protected]

Polymer reduction technology

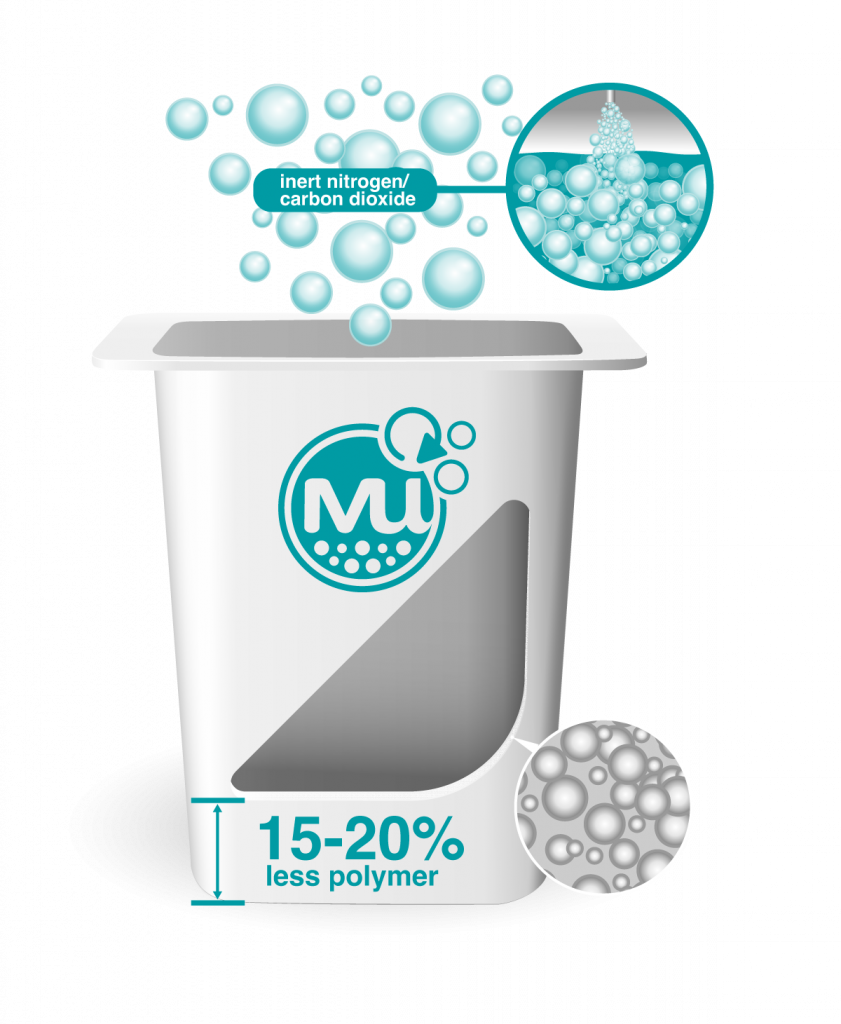

Patented technology from MuCell Extrusion LLC creates a lightweight centre in plastic extrusions by injecting pure atmospheric gas during manufacture. The result is a microcellular, or foamed, core within a solid skin – a single material that looks and performs like a solid plastic yet uses 15-20% less polymer.

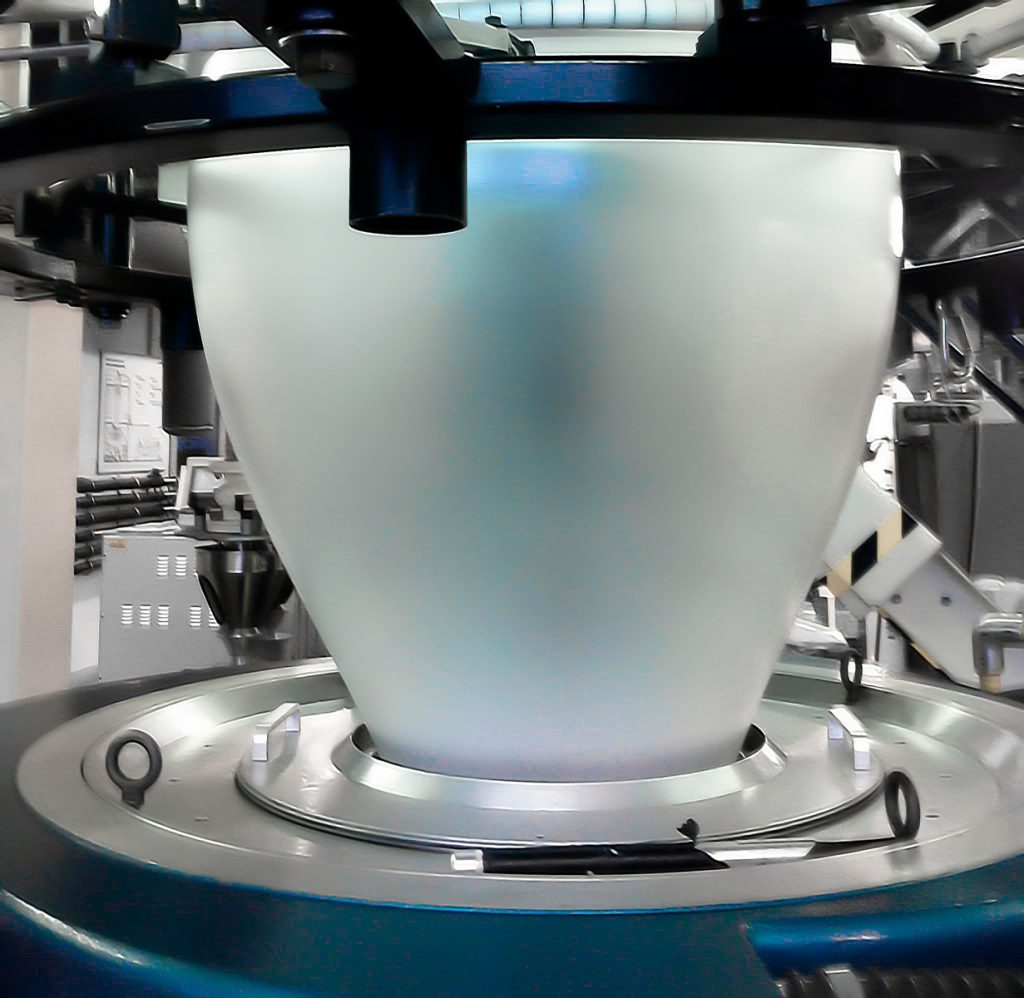

MuCell polymer reduction technology can be applied in a wide range of extrusion applications. These materials are then used to make products, such as pouches, sachets, trays, pots and other containers frequently used in volume in consumer packaging, reducing the carbon footprint right through the supply chain. And, after use, the products can be recycled in standard post-consumer waste streams.

Backed by significant know-how, MuCell Extrusion has successfully applied its polymer reduction technology to a wide range of polymers, including LDPE, LLDPE, HDPE, PS, PP, PA, PVDF, PET, PLA, PVC and TPE.

Produce lightweight alternatives to existing products. Design exciting new ones. Our technology is suitable for most polymers, and most extruded products can benefit from our lightweighting advantage. No wonder some of the biggest names in consumer packaging are using MuCell Extrusion polymer reduction technology to support their sustainability goals.

MuCell Extrusion polymer reduction technology uses inert nitrogen or carbon dioxide to reduce plastic content. Films and sheets made this way typically contain 15-20% less polymer than products made using traditional extrusion technologies. Enhanced mechanical properties deliver the same performance as a solid product – yet with significant cost and weight savings and environmental benefits.

Only atmospheric gases are added to the foamed polymer, avoiding harmful emissions and creating pure materials that can be recycled easily and cost-effectively. By replacing composite packaging – laminated paper, plastic and metal – with mono-material packaging solutions, our technology makes 100% recycling a reality.

And we help reduce raw material usage, creating a lower carbon footprint through less use of fossil fuel-derived plastics at manufacture and lower transport costs through the supply chain.

The substantial weight savings achievable yield significant cost savings on every unit produced, enhancing profits and sharpening your competitive edge.

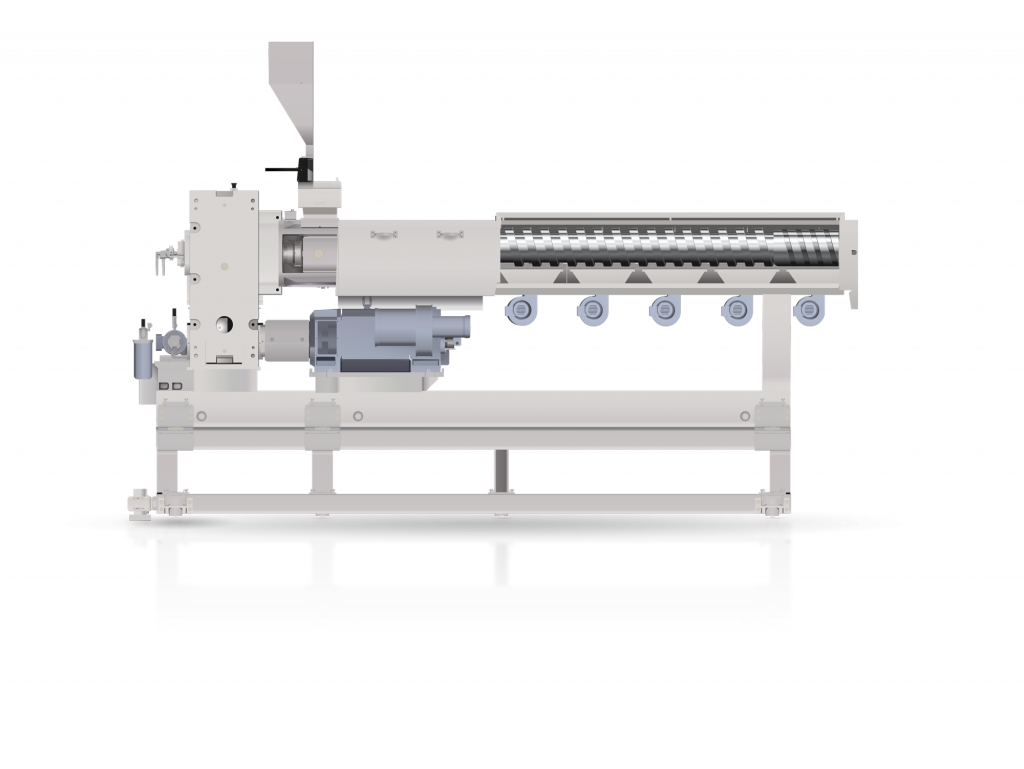

Our technology fits seamlessly into sheet and film extrusion lines, making light work of saving costs and reducing environmental impact.

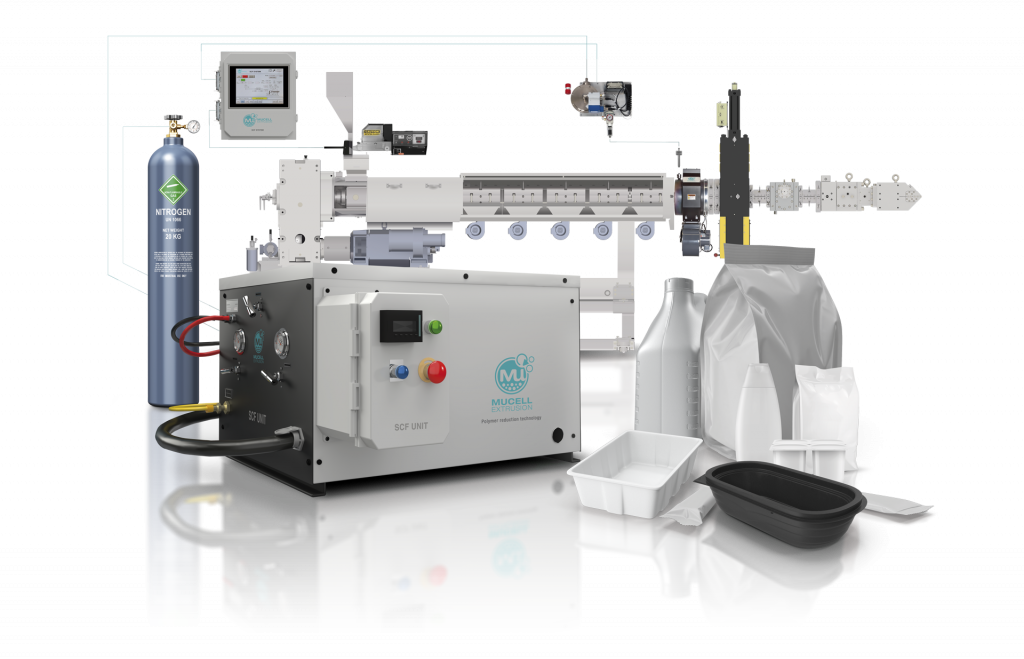

Three key components transform standard lines into microcellular extrusion lines. The MuCell SCF unit and Interface Kit pressurise, control and inject the gases in a Super Critical Fluid (SCF) state, and the MTM barrel extension mixes polymers and gas in a single-phase solution.

MuCell also supplies proprietary sheet and film dies that are optimised for microcellular foaming, as well as true gauge control systems.

This extraordinary technology is available from MuCell Extrusion LLC for applications in sheet and film extrusion. Our technicians work closely with customers’ new product development teams, using our development facilities in the USA and Europe to optimise material specifications and performance for each application.

The package price includes a one-off cost for intellectual property relating to your specific application, plus equipment and installation on a turnkey basis.

To discuss the benefits of integrating MuCell Extrusion’s technology into your lines, contact us today:

or call +1-781-281-7976